[UPSTREAM] * [DOWNSTREAM]

Bioprocess engineering deals with the design and development of equipment and processes for the manufacturing of products such as agriculture, food, feed, pharmaceuticals, nutraceuticals, chemicals, and polymers and paper from biological materials. The basic techniques of bioprocessing date back thousands of years with manufacture of beer, yogurt and bread. Niazi inventions reinvent the entire field of bioprocessing providing inventions into design of bioreactors, mixing systems, monitoring systems, contamination control, capture systems and finally purification of highly sensitive human use products.

- Upstream steps involve growth of genetically modified or unmodified living entities to express a desired product. Current bioreactors date back to thousands of years and even in their modern layout to over 180 years; a ground-up reinvention of upstream technology is developed by Niazi emphasizing use of single-use bioreactor, with minimal energy input, high reproducibility of complex products, operation uncontrolled environment and maximal protection during processing to address the futuristic needs of bioreactors to produce monoclonal antibodies and organs, on demand. These bioreactors open new research and development, fast to market, opportunities, all of which make high-end present and future therapies more affordable. The diversity of inventions provided here range from single-use systems, bioreactor exhaust controls, bioreactor monitoring and capture and purification in the bioreactor.

- Downstream: Harvesting and purification steps are the most expensive steps with greater risk to quality of products. Novel methods of combining capture steps with upstream reduce the cost significantly and improve the quality of products. Methods of capturing and purification of chemicals and drugs are refined to allow low cost manufacturing of biological products. Bioreactors are used for expressing a variety of chemicals and drugs; the next phase after upstream operation is capture and purification, the two steps that have historically required centrifugation and filtration, both of which cause significant loss of product and deterioration of product quality. The inventions described below use a method of first capturing the expressed product and then discarding the contents of bioreactor, eliminating two major costly steps. It is now possible to use a bioreactor to express and purify a product within the same container.

Single-use, full-bed aerated, filter-free, multi-motion bioreactor capable of continuous processing

Multiple bioreactor containers vertically disposed allowing gravitational flow through for continuous processing, recycling and protecting environment from exhaust allows processing of every category of product made in a bioreactor at a lower cost. PDF.

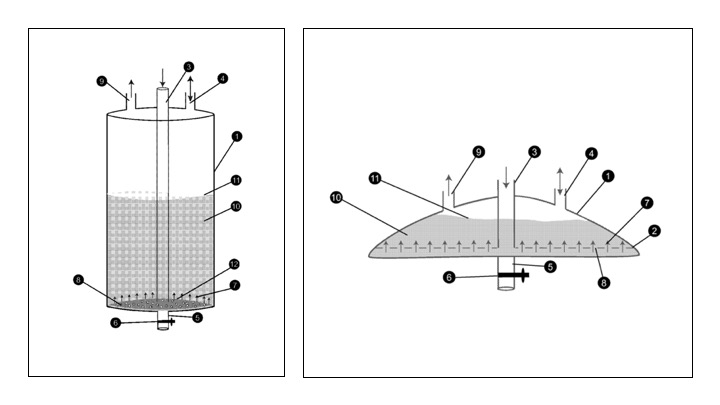

Perforated septum provides gassing throughout the base of the bioreactor, a capture function by introducing a binding resin above the septum--a single container manufacturing in a single-use system.

A septum is positioned within a disposable vessel and defines a lower chamber and an upper chamber. The septum includes a plurality of apertures that provide fluid communication between the upper chamber and lower chamber. Compressed gas is introduced in the lower chamber to produce fine bubbles rising throughout the vessel to produce a mixing and gasification needed for the growth of a biological culture and manufacture of a biological product in a nutrient medium. Adding a binding resin to the upper chamber allows harvesting, separation and purification of biological products in the reactor as a single unit operation. PDF

Multiple configurations including a single-use bioreactor kept stationary and mixing achieved through rising bubbles from the bottom.

Reactors that allow mixing and gasification by converting the entire floor of the reactor vessel to a sparge filter is described. A flexible horizontally disposed disposable bioreactor bag or a stainless steel structure disposed vertically are described, wherein gas is introduced through a perforated septum to aerate the nutrient medium. PDF

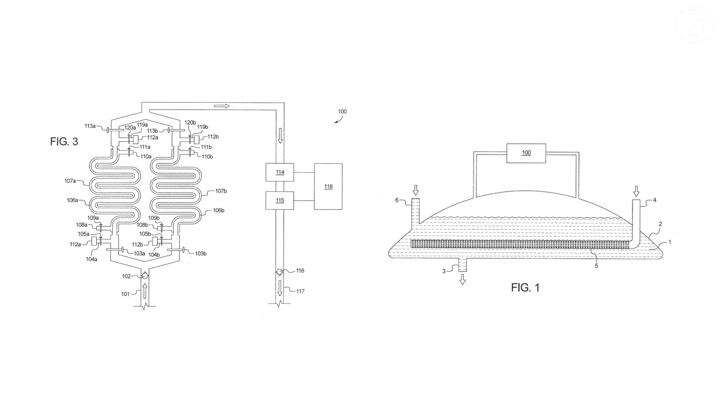

Recirculating exhaust removing carbon dioxide and adding nutrient gases; operable in uncontrolled environment with hazardous substances.

Bioreactors operating in uncontrolled environment such as required in situations like on-site production, handling extremely hazardous materials, etc., require a bioreactor that is completely closed. The exhaust is scrubbed of any components of exhaust such as carbon dioxide and entire exhaust gas returned to bioreactor with added nutrient gases, in a one-way operation. Many applications in related industries. Reduces cost of operations by not requiring clean rooms. PDF

Flaps compressing the edges of a flexible container produce wave motion without moving the container.

Stationary bioreactors and mixing vessels fitted with single-use flexible bags utilizing wave hydrodynamic principle are described for use in every type of biological process and products. Flaps are synced to create a harmonic motion or operated independently to any desired motion. Used for mixing, bioprocessing, chemical reaction with no limitation on size since the container remains stationary. PDF

Air-driven propeller in a single-use flexible bioreactor allows dual function of gassing and mixing without an external stirring device.

A single-use round flexible mixing bag where in culture media is agitated using an internal fluid-agitating element comprising a radial flow impeller driven by an internal pneumatic vane motor. The single-use container remains stationary, allowing large volumes for mixing and bioprocessing at a very low cost. PDF

Pressurized cylindrical container on rolling device wherein a flexible liner is pressurized to create two compartment and allows complete flow of liquid from one compartment to another to create mixing without rotating the container.

Pressurized hermetically sealed bags disposed inside a cylindrical support and containing a septum with variable density of porosity and dividing the bag into two chambers are used to provide optimal mixing and gasification of nutrient media to grow a variety of biological cultures, particularly the cell cultures to produce a multitude of pharmaceutical and biotechnology products in a disposable system. PDF.

Another patent application for device claim is pending under: US 15/053,804 | Pivoting Pressure Single Use Bioreactor.

Two flexible containers connected through a central channel providing gassing and mixing allow a see-saw motion for most efficient mixing and gassing.

A flexible disposable bioreactor having three, stagger-baffled compartments wherein the middle compartment houses a sparging rod is described to provide the highest degree of sparging and mixing to produce biological products. PDF

Gravitation mixing, geometric dilution mixing and linear mixing allows large scale bioprocessing using smaller containers and for pooling of batches from multiple bioreactors without the need for a large mixing vessel.

A method of homogeneously mixing the contents of a plurality of bioreactors by providing a receiving container to receive a fixed fraction of each bioreactor content repeatedly raising and lowering the receiving container to a position above or below the position of the bioreactors resulting in mixing the contents of the bioreactors. PDF

Single container manufacturing of biologicals wherein the expressed product is captured in a porous bag permanently disposed inside a bioreactor.

A bioreactor that combines the steps of recombinant expression and separation of a biological product by binding the secreted biological product with a resin, discarding the nutrient medium and eluting the biological product as a concentrated solution, eliminating the steps of sterile filtration and volume reduction. The method also allows loading of resin for column-purification, eliminating all steps of perfusion process and maintaining a sink condition of a toxic product in nutrient medium to optimize productivity of host cells. The instant invention also allows harvesting of solubilized inclusion bodies after the cells have been lysed and refolding of proteins inside the bioreactor. PDF.

US 9,200,335 | Separative Bioreactor.

A methods claim patent as a continuation of US 8,668,886. PDF

US 13/754,167 | Separative Harvesting Device.

A harvesting device claim for continuation of US 8,668,886. PDF

US 13/092,955 | Separative Bioreactor.

A methods claim application from continuation of US 8,668,886 and US 9,200,335. PDF

Radial aeration of bioreactors using solid sparging rods allows mixing function, removing need for external stirrers.

A vertical sparging element with pores smaller than about 50 mu and oriented vertically allows uniform distribution of gases and uniform mixing; the size of pores is adjusted to allow for pressure drop from the source of gas connection. PDF

A universal multi-use single-use bioreactor providing single container manufacturing DOE management, and continuous harvesting is described.

A multi use bioreactor that is a single-use bioreactor, a development bioreactor, a commercial manufacturing bioreactor, a batch, a fed-batch, a perfusion and continuous bioreactor, a convective heat bioreactor, a product capture bioreactor, an ISO 9 bioreactor, a eukaryotic bioreactor, a prokaryotic bioreactor, a technology transfer-free bioreactor, and an inexpensive bioreactor is disclosed. PDF

Sparging maze covering the entire base of a horizontal or vertical bioreactor with variable size porosity to mantain uniform pressure resulting in high kLa and mixing, allowing bioreactor to stay stationary.

An aeration and mixing device for disposable flexible bioreactors comprising a mesh of interconnected perforated disposable tubes to form a structure to cover essentially the entire bottom surface of a disposable flexible bioreactor and wherein a continuous flow of gases through the perforations in the tubes provides an aeration and a mixing function. ALLOWED

US 9,005,959 | Bioreactor Exhaust.

Cooling or freezing bioreactor exhaust to remove droplets, returning liquid back to the bioreactor and exhausting clean gas. A one-way exhaust to prevent contamination to flexible bioreactors. Low cost, prevents batch losses due to filter blockage, a major risk in upstream processing. PDF

Temperature controlled condensation to return liquids in a closed system.

A device application on the divisional basis is filed as US 14/685250 | Bioreactor Exhaust. and pending. PDF

Carbon dioxide is removed in a dual condenser in a recovery switch, recirculating exhaust for hazardous substances and to operate bioreactor in ISO9 environment.

A recirculating bioreactor exhaust apparatus to remove a gaseous element from the bioreactor exhaust, such as carbon dioxide, by freezing the gaseous element and then returning the remaining exhaust gas to the bioreactor and a method of use. PDF

By placing cuvettes in the bioreactor, direct monitoring of culture media without contacting is made possible using high end-emitters and detectors.

A pair of receptacles capable of housing an emitter probe and a detector probe installed inside a bioreactor to monitor the properties of the nutrient media without contacting the nutrient media. PDF

US 8,545,759 | Noninvasive Bioreactor Monitoring.

A pair or receptacles capable of housing an emitter probe and a detector probe are installed inside a bioreactor to monitor the properties of the nutrient media without contacting the nutrient media. method for monitoring a nutrient media in a bioreactor comprising: a. Disposing in a bioreactor at least one pair of receptacles suitable for housing an emitter probe or a detector probe wherein each receptacle comprises one open end in fluid communication with the outside of the bioreactor and one sealed end; b. Disposing an emitter probe in a one receptacle of the pair of receptacles; c. Disposing a detector probe in the other receptacle of the pair of receptacles; d. Adjusting the direction of the emitter and the detector probes to face each other to read transmitted radiation or to an angle to read diffraction of radiation; e. Activating the emitter and detector probes to record transmission or diffraction of the radiation applied to the nutrient media of the bioreactor. PDF

A float column with retaining system for resin automatically mixes content of multiple bioreactors and captures expressed protein.

Large-scale downstream processing method of secreted recombinant proteins is provided in a single device, wherein the contents of a plurality of bioreactors are combined simultaneous to their harvesting and purification resulting in significant savings of time and the cost of manufacturing. PDF

US 8,506,797 | Downstream Bioprocessing Device.

A device claim patent based on continuation of US 9,321,805. PDF

US 15/135,263 | Downstream Bioprocessing Device.

An expanded-bed adsorption chromatography method for purifying a target protein in a protein solution from continuation of US 8,506,797 PDF

US 8,932,843 | Buoyant Protein Harvesting Device.

A floating device at different heights in a bioreactor with a pouch to hold binding resin removes expressed proteins continuously and efficiently.

A buoyant device containing chromatography media performs the function of protein harvesting replacing the steps of cell separation and volume reduction; the device can be loaded into columns for further purification. The device rotates automatically under Brownian motion caused by strategically placed holes in the buoyant collar. PDF

US 9,290,732 | Buoyant Protein Harvesting Device.

A device claim patent based on continuation of US 8,932,843. PDF.

US 14/569, 012 | Buoyant Protein Harvesting Device.

A device claim based on continuation of US 8,932,843. PDF

US 15/076,337 | Buoyant Protein Harvesting Device.

A methods claim patent based on continuation of US 8,932,843 for harvesting refolded proteins. PDF

Single-use flexible bag to capture expressed protein, with or without aeration, and with two types of aeration, a septum and sparger, the former also acts as a separator of bound proteins.

A chromatography column that captures components in a process liquid in a free flow state and allows elution in steps is described. A disposable preparative chromatography column for effecting separation of components of a process liquid. Provisions are made for separating bound protein with resin and elution with purification steps. PDF

US 15/050,982 | Preparative Chromatography Column and Methods.

A methods claim patent based on continuation of US 9,284,346. PDF

US 13/246830 | Preparative Chromatography Column and Methods.

A device claim for continuation of US 9,284,346. PDF

Porous container pieces connected to required size containing biniding resin and introduced into bioreactor to capture and remove expressed proteins.

A purification and separation treatment assembly (PASTA) for biological products expressed in a bioreactor comprising a flexible porous tube filled with a binding resin and having a plurality of pores smaller in size than the size of the binding resin and sealed at both ends and at regular distances along the length of the mesh tube. A method for harvesting and purifying a target biological product at the end of a production cycle or during a production cycle. PDF

14/507, 469 | Purification and Separation Treatment Assembly (PASTA) For Biological Products.

A method claim application continuation of US 8,852,435. PDF

A single-use bioreactor capable of capturing expressed proteins; a third layer of perforated sheet, tufted to keep it from bloating, serves as a separation compartment. For end process or during process for perfusion. Protein can be eluted after washing in the same container.

A method of manufacturing biological products in a single container from the growth of cells to purification of the product is performed in a flexible disposable bioreactor that uses only a compressed gas for mixing and gasification. A porous septum is used to create the gasification and mixing as well as to separate a chromatography media used to harvest and purify a biological product in the same container. The closed container can be used in any environment without the risk of contamination to the product or the risk of contamination of environment with the product. This allows large manufacturing of hazardous substances, drugs and vaccines anywhere at the lowest cost possible. Numerous applications can be found in counter-terrorism and biodefense operations as well in managing epidemic illnesses. PDF

A modular column with pods or pucks holding same or different resins to drain bioreactor content to capture expressed proteins.

A modular device comprising one or more porous substrate subunits comprising a binding substrate that can interact with a target biological product, either during, or at the end of a manufacturing cycle; and methods of using the device to harvest or purify a biological product. ALLOWED. PDF

US 13/083,589 | Protein Harvesting.

Methods of harvesting proteins directly from bioreactors to avoid at several steps in the purification of recombinant drugs are disclosed. A method of harvesting a target protein from a liquid in a first container comprising: A means of contacting said target protein with a resin capable of binding substantially all of said target protein to form a protein-resin conjugate; A means of separating said protein-resin conjugate from said liquid; A means of recovering said target protein from said protein-resin conjugate. PDF

go up